The Coldscape

From the tank farm to the sushi coffin

Nicola Twilley

More than three-quarters of the food consumed in the United States today is processed, packaged, shipped, stored, and sold under artificial refrigeration. The shiny, humming stainless steel box in your kitchen is just the tip of the iceberg, so to speak—a tiny fragment of the vast global network of temperature-controlled storage and distribution warehouses cumulatively capable of hosting uncounted billions of cubic feet of chilled flesh, fish, or fruit. Add to that an equally vast and immeasurable volume of thermally controlled space in the form of shipping containers, wine cellars, floating fish factories, international seed banks, meat-aging lockers, and livestock semen storage, and it becomes clear that the evolving architecture of coldspace is as ubiquitous as it is varied, as essential as it is overlooked.

J. M. Gorrie, a Florida doctor, was awarded the first

Despite the efforts of industry bodies, government agencies, and industrial archaeologists, this vast, distributed artificial winter that has reshaped our entire food system remains, for the most part, unmapped. What’s more, the varied forms of these cold spaces remain a mystery to most. This guide provides an introduction to a handful of the strange spatial typologies found within the “cold chain,” that linked network of atmospheric regulation on which our entire way of life depends.

These are spaces in which a perpetual winter has distorted or erased seasonality; spaces that are located within an energy-intensive geography of previously unimaginable distance—both mental and physical—between producers and consumers. Artificial refrigeration has reconfigured the contents of our plates and the shape of our cities—it has even contributed to the overthrow of governments, as anyone familiar with the rise and fall of United Fruit can attest. Perhaps most bizarrely, although their variations in form reflect the particular requirements of the perishable product they host, coldspaces have, in turn, redesigned food itself, both in terms of the selective breeding that favors cold-tolerance over taste and the more fundamental transition from food as daily nourishment to food as global commodity.

Welcome to the coldscape: the unobtrusive architecture of man’s unending struggle against time, distance, and entropy itself.

These early shipments, however, were unreliable. Barbara Pratt, who runs a pick-your-own apple farm in addition to being Maersk’s director of refrigerated technical services, told me that when she joined the industry in the late 1970s “sometimes refrigerated shipments would arrive

To develop a science of refrigerated shipping, Pratt spent nearly seven years—most of her twenties—working and living in a refrigerated shipping container, complete with two bunk beds, a microwave, a refrigerator, a shower, and, most importantly, a fully equipped science lab. In addition to monitoring temperature, Pratt mapped airflow, humidity, plant respiration rates, and more within the containers. Her findings, combined with the invention of the microprocessor, completely redesigned reefer units, moving the airflow from the top to the bottom, adding air exchange vent capacity, and developing variable humidity, temperature, and gas regimes that were optimized to the particular needs of bell peppers, watermelons, pineapples, and avocadoes.

Sensor networks and satellite communications mean that shipping companies can keep an eye on their perishables round the clock today, making minute adjustments in oxygen levels in response to such variables as asparagus respiration rates. Thanks in no small part to Pratt’s research, the reefer has triumphed as a reliable and ubiquitous link in the global cold chain—to the extent that it is now encroaching on other coldspace typologies, such as the banana rooms and meat lockers described below, by recreating their ripening and dry-aging regimes en route.

These underground limestone caves are natural refrigerators, maintaining a constant cool temperature (usually between 45° and 58°F). Unlike your average Frigidaire or SubZero, however, a damp, drafty cave also offers cheese the high humidity levels (above 80 percent) and air circulation that it requires. As an added bonus, different caves feature their own unique combination of bacteria, yeast, and mold: for example, the caves of Roquefort-sur-Soulzon in France harbor a particular strain of Penicillium, which is responsible for the cheese’s characteristic blue veins.

Over in the New World, Kraft also stores its cheese underground—in giant yellow drums, stacked five high, alongside Oscar Mayer meats and Jell-O puddings. Their four-hundred-thousand-square-foot subterranean warehouse and regional distribution center is housed in a disused section of a limestone mine, rather than a natural cave, in Springfield, Missouri.

The mine, which was begun in 1946 to extract agricultural lime and now produces aggregate for construction, is a hundred feet below ground, and thus maintains a steady 58°F—analogous to a natural cheese cave. Some of the blasted rock walls and the ceiling in the Kraft rooms have also been left au naturel, albeit accessorized with special anchors to hold lights and fixtures. But the similarities to traditional affinage end there: Kraft’s industrial cheese cave is underground—alongside an increasing volume of refrigerated data centers and photo archives, as well as food storage—for reasons that involve energy savings rather than terroir. The facility’s manager, Tony Snyder, estimates that Kraft uses 65 percent less electricity than a comparable surface warehouse, even though they rely on a chilled brine pumping system to bring the temperature down to a much less microbe-friendly 36°F.

Interstate-adjacent, with below-ground truck docks and rail sidings, as well as forty-five-foot ceilings to accommodate cranes, booms, and lifts, these kinds of titanic, fluorescent-lit, artificially refrigerated underground caverns increasingly house our food, our data, and our most valuable cultural artifacts.

In the 1960s, vacuum packaging allowed producers to “wet age” beef, sitting in a plastic bag in its own juices for two weeks. This process saves time and refrigeration costs, while resulting in less shrinkage. Such compelling benefits to the industry’s bottom line meant that by the 1980s, more than 90 percent of American beef came to market in this form, despite the unfortunate fact that wet aging results in “a more bloody/serumy flavor,” according to the Department of Food Science and Nutrition at the University of Minnesota.

Nonetheless, there are still some dry-aging rooms, or meat lockers, to be found. I visited Master Purveyors in the Bronx, which supplies most of the high-end steakhouses in New York. Founded and run by Holocaust survivor Sam Solasz, the family business selects, cuts, and ages short loins, striploins, and ribs from roughly 10 percent of what they describe as “the best cattle in the country”: beef of native Angus descent and graded prime by the USDA.

On an average day, $1.4 million worth of meat sits on wire shelves in Solasz’s sixteen-hundred-square-foot, 34°F dry-aging rooms. A given piece of meat typically spends twenty-one days there, where it shrinks in size by 15 percent while increasing in value by 20 percent. In addition to its preferred temperature, prime steak’s environmental requirements include 80 percent humidity levels—as high as possible to reduce shrinkage, without risking pathogenic bacterial growth—and constant air flow to ensure a uniform drying rate (at Master Purveyors, this is provided by an army of carefully placed standing fans).

As a result, meat locker visitors (who include many of the city’s best chefs, armed with a stamp to mark their purchases) walk down fluorescent-lit, white-tiled aisles surrounded by purpling, mold-covered primal cuts and chased by gusts of malty, mushroomy, slightly sweet-smelling air. Of course, according to Mark Solasz, Sam’s son, “it’s not a smell, it’s an aroma.”

What this means is that ripening must then be artificially induced in a specialized architecture of pressurized, temperature- and atmosphere-controlled rooms that, contrary to logical expectation, require heavy-duty refrigeration. Paul Rosenblatt, who runs Banana Distributors of New York, one of four main banana-ripening outfits supplying the city’s grocery stores, bodegas, coffee shops, and food cart vendors, told me that “the energy coming off a box of ripening bananas could heat a small apartment,” requiring not just refrigeration but also a series of fully pressurized and vented rooms in order to suck the cool air through the closely packed fruit.

Rosenblatt aims to keep his bananas in the ripening rooms for five days at a steady 62°F, although, to schedule fruit-readiness in accordance with supply and demand, he can push a room in four days at 64°F, or extend the process to seven days at 58°F.

In addition to precise temperature control, the ripening process also depends on atmospheric design. Over a twenty-four-hour period, each roomful of bananas is gassed with ethylene, a plant hormone that accelerates ripening and that smells disgusting—like a pub carpet after a night of spillage. Today, Rosenblatt uses portable “Easy-Ripe” low-flow ethylene generators, but in the early days, the rooms were injected with a burst of gas released from a cylinder, which, as ethylene is highly flammable, made banana-ripening room explosions quite common, and sometimes fatal.

Tomatoes and avocados also have their own ripening rooms, with different refrigeration, humidity, gas, and air flow requirements, although the entire ripening room typology is now under threat from sophisticated reefer units that can build variable climatic regimes into the journey time in order to unload ready-ripened bananas at the dock.

To engineer a consistent supply of a highly perishable product, Big Juice (Tropicana, Florida’s Natural, and their ilk) pasteurize, de-oil, and then strip the oxygen from their

There, according to Alissa Hamilton, author of Squeezed: What You Don’t Know About Orange Juice, it often sits for as long as a year, from processing season to processing season, before being rejuvenated with the addition of specially formulated flavor packs (to ensure each brand maintains its own trademark taste), and shipped to a distribution center in Jersey City on the refrigerated box cars of the

Bulk liquid juice storage was first introduced in the mid-1980s, adapting a decade-old technique originally developed at Purdue University to store crushed tomatoes. Previously, ready-to-drink orange juice had evolved from canned “battery acid,” available from the turn of the nineteenth century, to reconstituted frozen concentrate, which rose to dominance in the postwar grocery store.

As not-from-concentrate “Pure Premium” juice began to catch on in the 1980s, juice companies at first built long, narrow, walk-in freezers, storing fresh

Tropicana (a Pepsico company) was the industry leader, building 250,000-gallon stainless steel, individually insulated and refrigerated storage cylinders in an outdoor “tank farm” at its Bradenton, Florida, facility in the mid-1980s. Today, tanks typically boast capacities of a million or a million-and-a-half gallons, and the farms are completely enclosed in refrigerated rooms. Simply Orange—owned by soda rival Coca-Cola—recently celebrated the inauguration of a twenty-five million gallon indoor tank farm eighty miles inland at Auburndale. With more than one hundred million gallons of capacity in Florida supplying more than one in five Americans with their daily

As Sasha Issenberg’s The Sushi Economy explains, Okazaki happened across tuna as the solution to a very particular problem: when

After poring over the United States’ handbook of federal trade statistics, Okazaki determined that seafood’s “value and sensitivity to decay perfectly matched the economics of air freight,” and that Atlantic bluefin were worth significantly more in Japan than Boston. The only problem was how to keep tuna fresh over a journey of more than ten thousand miles.

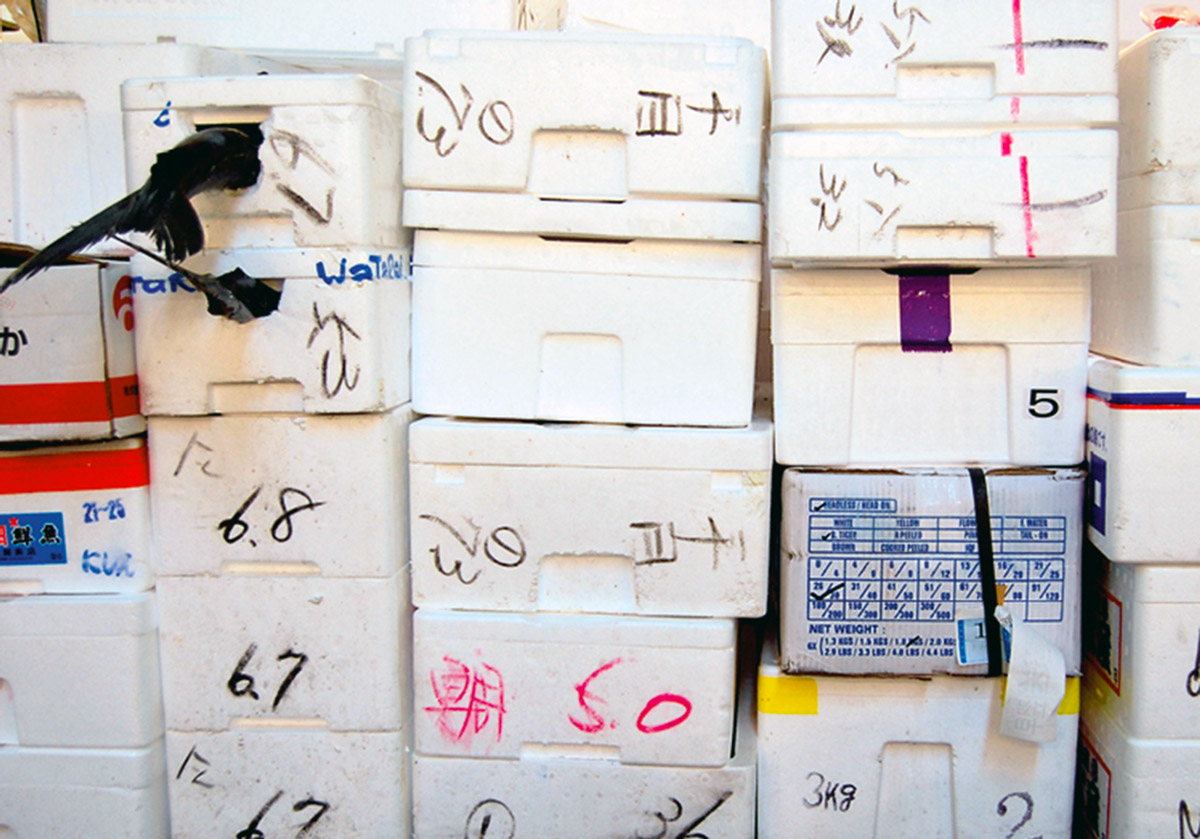

After extensive experiments involving spray urethane, ice chips, newspaper, vinyl bags, and a pair of Canadian coffin makers, Okazaki and the

Today, the leak-proof expanded polystyrene boxes (a Norwegian invention) in which fish travel are still called coffins, the “ref-cons” (refrigerated cargo containers) in which they are stowed are built from lightweight but well-insulated composite aluminum, and the design of Boeing’s jumbo jet is much more cargo-friendly. Meanwhile, the Atlantic’s previously plentiful bluefin have migrated by air at such a rate that they are now considered an endangered species.

This article was corrected on 18 August 2014. It misstated the size of Master Purveyors dry-aging rooms, which are 1,600 square feet, not 16,000 square feet, as originally stated. The article has been updated to reflect the correct size. Additionally, the article originally originally stated that Master Purveyors select, cut, and age “up to 10 percent of all USDA-certified prime Angus beef in America,” whereas in fact the USDA certification simply refers to beef graded as prime, and is not breed-specific. The article has been updated to reflect the correction, as well as to clarify that the Master Purveyors is only purchasing specific cuts, rather than the entire carcass, from Angus and Angus cross-bred cattle.

See press about “The Coldscape” on hereandnow.wbur.org.

Nicola Twilley is author of the blog Edible Geography; co-founder of the Foodprint Project, an international conversation series on food and the city; and co-director of Studio-X NYC, part of the Columbia University Graduate School of Architecture, Planning, and Preservation’s global network of advanced research laboratories for exploring the future of cities. She is curator of a forthcoming, Graham Foundation–supported exhibition at the Center for Land Use Interpretation examining North America’s coldscape and is currently expanding her research on the artificial cryosphere into a book.

Spotted an error? Email us at corrections at cabinetmagazine dot org.

If you’ve enjoyed the free articles that we offer on our site, please consider subscribing to our nonprofit magazine. You get twelve online issues and unlimited access to all our archives.